Equipment for tunnel laundry and dry-cleaners

Industrial tunnel type laundry with capacity of

|

1 700 000 $

|

|

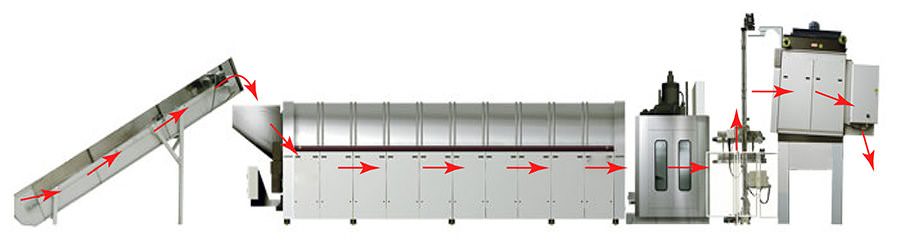

The principle of the tunnel washing line

The principle of the tunnel washing line

Tunnel factories are designed to reduce significantly production cost of finished products and therefore to create more competitive capability. Tunnel factories have a geography in a radius of 200km.

In order to start this type of enterprise you need to complete the following activities that our company has performed many times.

WORKS, SERVICES

|

Item |

Name | Performed actions | ||

| 1 |

Selection of premises |

Selection of premises for factory, calculation of technical specifications |

||

| 2 |

Scheme of technological equipment spotting |

The equipment spotting basing on premises structure in accordance with |

||

| 3 |

Project |

Issuing technical project documentation basing on the following sections: Architecture, Technology, Water supply system, sewerage, electricity supply and lighting, heating system, ventilation, low power networks, automatic fire-alarm system. |

||

| 4 |

Field supervision |

Action coordination of contractors, execution control of design works (4 on-site visits). |

||

| 5 |

Preparatory redecoration |

Screed, underpinning, floor reinforcement, construction of sewage pipes and floor gullies, covering with moisture-proof paint, organization of technological partitions, using water-resistant materials for toilets and shower sanitary inspection centers. |

||

| 6 |

Sanitary engineering work |

Installation of sewerage, water supply system for hot water, cold-water, water meter unit with water treatment, water softening and pumps with increasing pressure, gearboxes, manometers. |

||

| 7 |

Electrical installation work |

Assembling and installation of electric service panel, lighting, electric equipment. |

||

| 8 |

Ventilation, heating system |

Installation of ventilation and heating systems. |

||

| 9 |

Steam supply lines |

Setup steam supply to the equipment, air-traps and return system (copper, insulation). |

||

| 10 |

Automatic fire-alarm system |

Installation of automatic fire-alarm system. |

||

| 11 |

Delivery, tackle system |

Tackle system, unloading, equipment arrangement, dismounting from pallets, unpacking. |

||

| 12 |

Supervision installation, commissioning works |

Start up, equipment programming, use training -7% from equipment cost including consumable costs. |

||

| 13 |

Staff training |

Staff training to learn washing technologies, training of technical personnel to operate and maintain equipment, service regulations |

||

| 14 |

Documents collection for approval |

Conclusion of the contract for solid waste disposal, demercurization, hazardous waste disposal, disinfestation, water supply and wastewater disposal. |

||

| 15 |

Fire protection activities |

Fire prevention measures, evacuation plan, navigation of escape directions, instructions, magazines, fire extinguishers, supports, stickers. |

||

| 16 |

Execution of documents for staff |

Training and certificates reflecting information about basic fire safety training, labor protection and electrical safety for managers and senior officials. |

||

| 17 |

Program of a manufacturing control |

Production control program. Measurements of noise, light, and climate. |

||

| 18 |

Performance appraisal system |

Qualification reports (Agency for Health and Consumer rights), documentation for labor inspection. |

||

| 19 |

Agency for Health and Consumer rights |

Notification, Certificate of conformity. |

||

| 20 |

Fire safety authority |

Fire safety declaration |

||

| 21 |

Control system |

Remote access, installation, setup IP-video, accounting program setting, creation of basic price-lists. |

||

| 22 |

Consulting |

Layouts of contracts, forms, magazines, marketing, consulting, negotiations with potential customers. |

||

| 23 |

Advertising campaign |

Yandex 1 line of region for 1 year |

||

| Total: | ||||

CONSTRUCTION WORKS

| Item № |

Name | Performed actions | Area |

| 1 |

Preparing of foundation |

Reinforcement, sewerage, gully. |

1200 sq.m. |

| 2 |

Construction of prefab building |

delivery and installation on prepared foundation |

1200 sq.m |

| 3 |

Head well |

|

|

| 4 |

External lines conduit |

|

|

Tunnel type laundry |

RFID equipment textile, laundry and dry-cleaners |